Growth continued as the company built complete machines, rebuilds and parts for paper mills in the Midwest, Canada, and as far away as Texas. IN 1891 the company made the first complete Yankee machine ever build in the United States. In 1893 it was invited to build and install a paper machine at the Chicago World’s Fair, the Columbian Exposition. The machine operated at the fair with a full crew and received the United States Columbian Award for a “very his standard of workmanship and productiveness.”

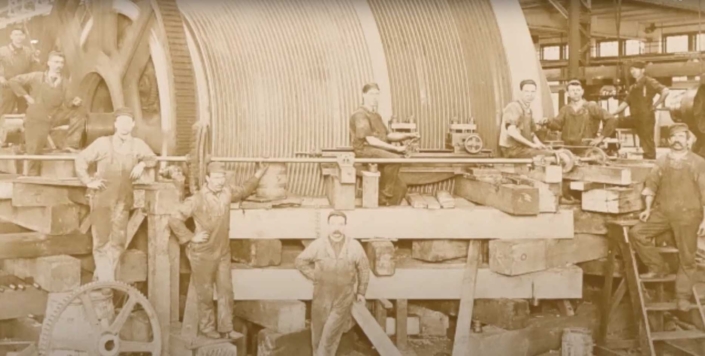

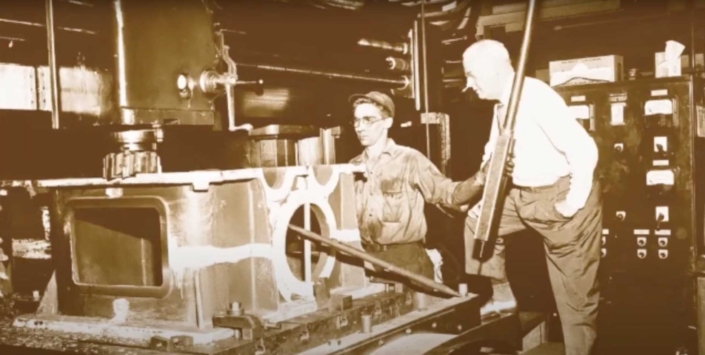

Demand for paper was growing rapidly in this period, paper mills were prospering, more machines and rebuilds were being ordered, and the machines themselves were larger. The first machines made in Beloit had been as small as 30 inches wide, but in the 1890’s machines wider than 100 inches were being designed. So the company had to undertake an expansion program. More land was acquired on the West side of Rock River spreading out from the island that has been part of the original Merrill and Houston property. In 1896 a new foundry was built as well as a new machine shops and offices. The more modern equipment was installed, able to handle the larger castings now required. Buildings were of brick and glass, much better than the wooden buildings they replaced, and heated also. In this year about 150 men were employed working on paper machines that sold for $25,000 to $30,000 each.

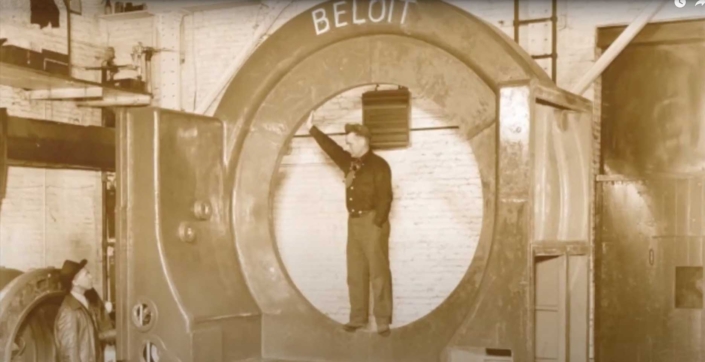

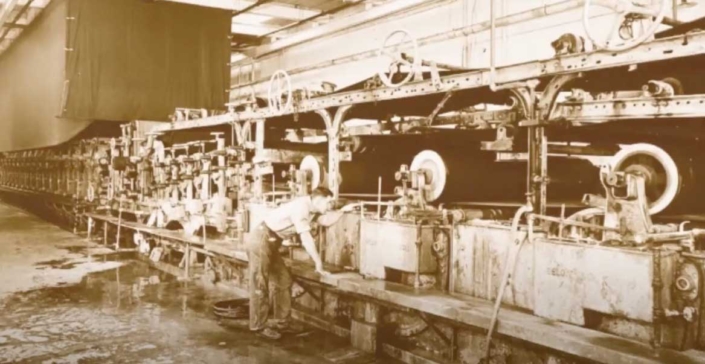

Technology was changing rapidly. Good quality paper could be produced on machines that ran much faster than before. In 1900 a Beloit cylinder machine would produce about 75 feet a paper per minutes; fourdrinier machines were making 400 to 500 feet per minutes. In 1910 a cylinder machine was designed for 300 feet per minute and a fourdrinier machine for 600.

Buyers of Beloit paper machines before the turn of the century were generally companies in the Great Lakes region, but in 1897 a machine was shipped to Japan, and two went to China in 1900. Beloit had become well-known in the industry, both nationally and internationally, in part probably because of the machine at the Columbian Exposition.

As the first years in the 20th century passed, though demand for paper was growing, machinery builders had lean years as well as good years. When Beloit’s shops were not busy, time and money were spent on improving facilities to be ready for the next surge of orders. Improvements in design of the paper machine were always important. Beloit machines continued to break records in speed as well as production. With the team of outstanding men her hired and promoted over the years, Alonzo Aldrich kept the company in the forefront of the industry.

One of the bright young men he hired was Elbert H. Neese, just thirty years old, who was vice-president and sales manager of a competitive machine builder, and also the husband of Laura, Mr. Aldrich’s only child. Elbert Neese, who already had 13 year’s experience in the industry, quickly became a strong factor in the management of the company, and with his help Beloit Iron Works increased sales rapidly. In 1916 when he came, sales were at their record up to that time; in the next 15 years the grew eight-fold.

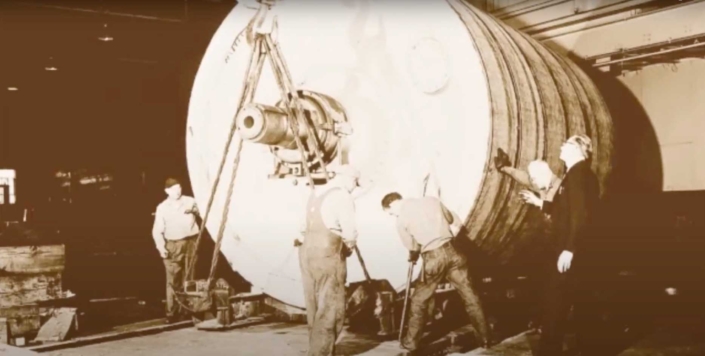

Because of this surge in sales, and since paper machines were being built ever wider, again there was a need for rapid expansion of facilities. The machine shop was enlarged and tools were updated so they could make machines wider than the 100 inches possible before. Employment reached a peak of 550 in the year 1930. Money was spent on design improvements, to increase the speed of production and improve product quality. Beloit led the industry and became known for superior machines with the most advanced design. An the company worked with its customers closely, to know their needs and to help solve their individual problems.

Alonzo Aldrich died in 1931 and was succeeded as president by Elbert Neese, Jr. Neese was faced with the worst years of the Great Depression. Orders for complete machines were non-existent, and parts and repair orders were scarce. The work force shrank to 180. A slight upturn occurred in 1933, and gradual recovery took place the following years until the 1937 employment reached a temporary 640.

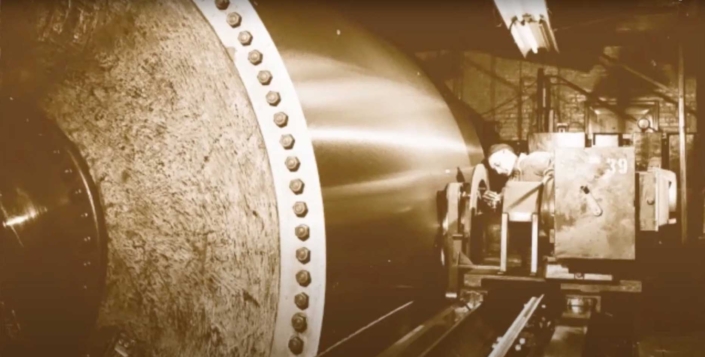

In 1941 Beloit Iron Works turned part of its production to war materials, building machine tools needed for war production. By 1942 nearly 100% of its capacity was being used for crankpin-turning lathes, boring mills, and powder mills. During the next three years the company build nearly 100 78-ton Corvette engines for the U.S. Maritime Commission. The Iron Works received the Army-Navy “E” for Excellence Award in November of 1943 and three times thereafter.

It was during this war period that the National Labor Relations Board ordered an election, and the International Association of Machinists, A. F of L. Was recognized as bargaining agent for the machine shop employees, the first union to be recognized by the Iron Works.

To handle the pent-up demand for larger paper machines in the years following the war, capacity was added, land was acquired, the tail race which had separated the island was filled in, new buildings and modern machine tools put into operation. Beloit paper machines were soon again breaking records for speed and production. In 1947 a tissue machine was furnished which ran 2800 feet per minute. The world’s largest cylinder machine was installed to produce board at a speed of over 500 feet per minute. By 1950 the first tissue machine was designed for a speed of 3000 feet per minute.

The work force was growing rapidly during this prosperous period. There were about 1,000 employees in 1946; 1300 in 1947; and 1450 in 1948. Employment reached 1690 in 1952, the year in which Elbert Neese, Sr. became Chairman and Harry C. Moore, who had started work at Beloit in 1937, became president.

Harry Moore, dynamic and charismatic like Mr. Neese, also shared his keen interest in expanding sales. The company spread its wings with the opening in 1949 of a sales office in Paris to promote Beloit machines throughout the world. During the 1950’s as much as a fifth of all shipments were to foreign countries.

A West Coast sales office was opened in Portland, Oregon, followed by one in Mobile, Alabama. Purchase of the foundry and machine shop facilities of the Downingtown Manufacturing Company in Pennsylvania in 1955 was the first of a series of acquisitions to increase production and to diversify. Next was a factor in Italy; then E. D. Jones & Sons Company in Pittsfield, Massachusetts in 1958, Beloit machines were soon being manufactured in England, Japan and Spain in production facilities owned or licensed by Beloit.

Important in the development of the company were the establishment of a research facility in Beloit in 1955 and the 1961 completion of a Research Center in Rockton, Illinois, a few miles from the Beloit plant. Beloit was enabled to focus its ability to innovate and to further enhance its technological leadership.

Elbert H. Neese participated in the dedication of the new Research Center, but died unexpectedly in August of 1961. As Chairman he had been influential in the company until his death.

The name “Iron Works” no longer seems to describe the company’s activities and further diversification was planned, so the company officially became “Beloit Corporation” on January 1, 1962.

A search for new products began as the company tried its hand in a variety of new endeavors, some related, some not related to the paper industry. Licenses were signed with firms in Poland and India for building Beloit paper machinery. The first turn-key project for an integrated pulp and paper mill was completed for Orient Paper Mills, India, in the mid-60’s. Wheeler Roll Company in Kalamazoo, Michigan was acquired in 1966.

During Harry Moore’s leadership Beloit became the major paper machinery builder in the United States and, with its licensees, in the world. Even as the industry became mature, sales continued to grow almost every year. Beloit’s technical lead was strong, its patents numerous, its innovations valued. Moore became Chairman at the end of 1974, the position he held until his retirement in 1978. He was succeeded by Elbert H. Neese, Jr. as president, and later as chairman.

Company growth continued with the purchase of Lenox Machine Company, the Rader Companies, the Roll Covering Division of Raybestos Manhattan, and the minority shareholdings in Beloit’s overseas plants. A new partnership was formed and a manufacturing plant built in Brazil in 1980. Efforts at diversification were again made in a variety of fields: insurance, railroading, agribusiness.

Facility expansion and improvements occurred in all divisions. The company making large investments to maintain and increase its technical lead with new research facilities in Pittsfield, Massachusetts; Lenox, Massachusetts, and Bolton, England. New Machine tools greatly increased the capacity to build the largest paper machines.

From its beginnings with 15 people to the 1980’s with 7700 employees, Beloit Corporation made steady, sometimes spectacular, progress through the energies and effort of the many dedicated, innovative, skillful people….engineers, salesmen, foundry men, managers, machinists, researchers, clerks….who earned for Beloit its pre-eminent position in the building of paper machinery.

Written by Mrs. Margaret Knorpp Neese, 1984, for “Sparks from the Flaming Wheel” edited by Joseph W. Rhodes.

EPILOGUE

In 1985 Chairman Elbert H. Neese, Jr. announced that the Neese Family had made a decision to sell Beloit Corporation, the decision based upon family financial interests.

In 1986, Harnischfeger Corporation of Milwaukee, purchased Beloit Corporation for $175 Million, and the management and control of Beloit Corporation left Beloit and was assumed by its new owner in Milwaukee.

In 1999 Harnischfeger Corporation filed a Chapter 11 petition for Bankruptcy, and as the bankruptcy proceedings moved through the Court System, the Beloit Corporation employees were let go, and its Beloit facilities were closed forever.

The memory of Beloit Iron Works and Beloit Corporation is preserved by the thousands of men and women who worked there. As an outstanding community leader and benefactor, its contribution to the growth and betterment of Beloit, is beyond measurement, and is recalled by murals on Rock River placed on the factory facilities by the new owners of those facilities.

Orson Merrill’s brother, Sereno T. Merrill, owned the Rock River Paper Mill Company, situated close to Merrill and Houston on the Rock River. In 1860 Sereno Merrill asked his brother to make parts for his paper machine, which has been bought in New England. The parts were highly satisfactory, and other local paper mills soon were ordering parts from Merrill and Houston. The quality was good, and the parts did not have to come all the way east as before. By 1862 Merrill and Houston was producing complete paper machines, building four in that year and several years thereafter, along with water wheels and other iron products.

Orson Merrill’s brother, Sereno T. Merrill, owned the Rock River Paper Mill Company, situated close to Merrill and Houston on the Rock River. In 1860 Sereno Merrill asked his brother to make parts for his paper machine, which has been bought in New England. The parts were highly satisfactory, and other local paper mills soon were ordering parts from Merrill and Houston. The quality was good, and the parts did not have to come all the way east as before. By 1862 Merrill and Houston was producing complete paper machines, building four in that year and several years thereafter, along with water wheels and other iron products.